GENUINE FLEXIBILITY DURING COMPONENT PRODUCTION

Your workpieces impose particular requirements on materials, geometries, raw materials and batch sizes. This is why WINEMA is developing customized transfer machines for the production of long runs, families of parts and component variants, all in optimum batch sizes. The best thing to do is to talk to us at the project planning stage.

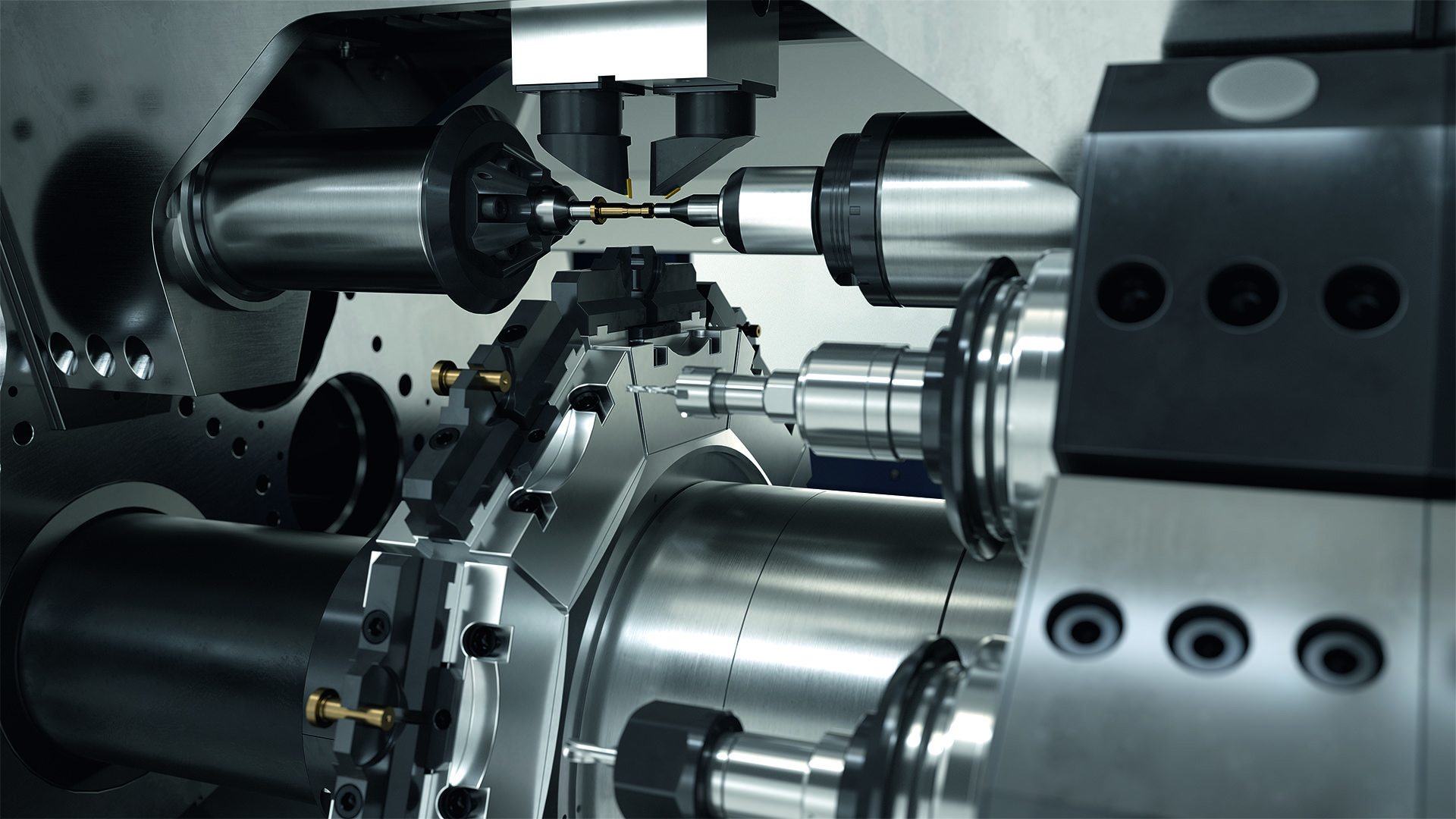

As a closed, internally rigid design, the PTC can transfer the workpiece into an independent coordinate system where it can conduct a turning process in isolation. The vibration-damped cast design disconnects the turning process from the machining factors that affect the other stations. By turning between tips, concentricity requirements that used to be critical can be manufactured without any problem down the entire length of the workpiece.

If the workpiece is held in a collet chuck by the PTC, tight positional tolerances can also be maintained between external and internal contours, all within a reliable process context. Two turning tools with Capto interface are integrated in every PTC. Three PTCs can be used in each machine (WINEMA RV10 Flexmaster).

• Complete machining of the external contour

• Internal machining is possible

• Optimum concentricity position when turning between tips

• Up to 3 modules can be used in a machine