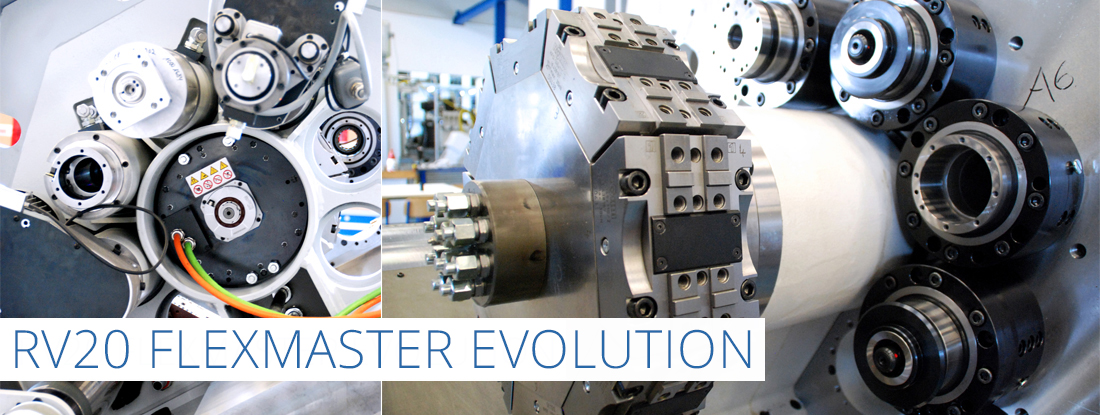

RV20 FLEXMASTER EVOLUTION

The WINEMA RV 20 Flexmaster Evolution is the further developed RV 20/8 Flexmaster. This CNC controlled rotary indexing machine is designed for the machining of parts in one setting. The typical diameter is between 4 and 30 mm, from the bar up to 42 mm. The RV 20 Flexmaster Evolution has a indexing table with 8 clamping stations. The workpieces can be machined by maximum 14 axial units and 3 radial units.

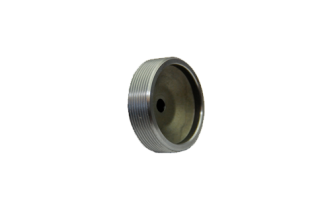

In addition there is the possibility for a plunge cut unit before the piece is clamped in the indexing table (up to 20 mm diameter). With this unit the outside diameter can be machined and afterwards be clamped on.

For the machining of pipes or profiles with the standard collet-chuck feeding, bars up to 42 mm diameter can be fed and sawed. The length of the parts can be up to 180 mm.

The feeding of the saw is now positioned on a linear slide which allows to carry out the positioning of the saw and the lift of the saw as a CNC controlled movement. This is very important for the sawing of pipes with thin walls. The complete new saw drive makes high speed sawing of workpieces up to 42 mm diameter possible.

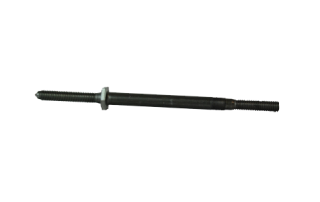

The newly developed main spindle unit combines the feeding of the bars with a plunge cut operation before the workpiece is clamped into the indexing table. With this unit the plunge cut before the clamping is also possible with bar feeding without causing long rest pieces. During the plunge cut, the work- piece is solidly clamped in a standard collet chuck.

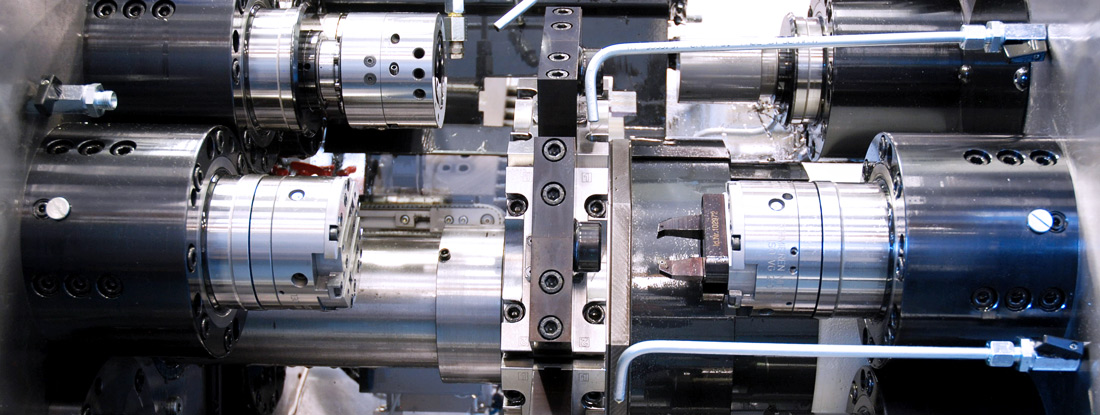

Due to a newly designed working area, there is more space and the possibility for an additional machining station or a gripping application for sensitive parts at the final station.

The unit carriers and the console of the drum are now equipped with inner cooling for higher temperature stability and even higher machining precision.

The unit carriers and the console of the drum are now equipped with inner cooling for higher temperature stability and even higher machining precision.

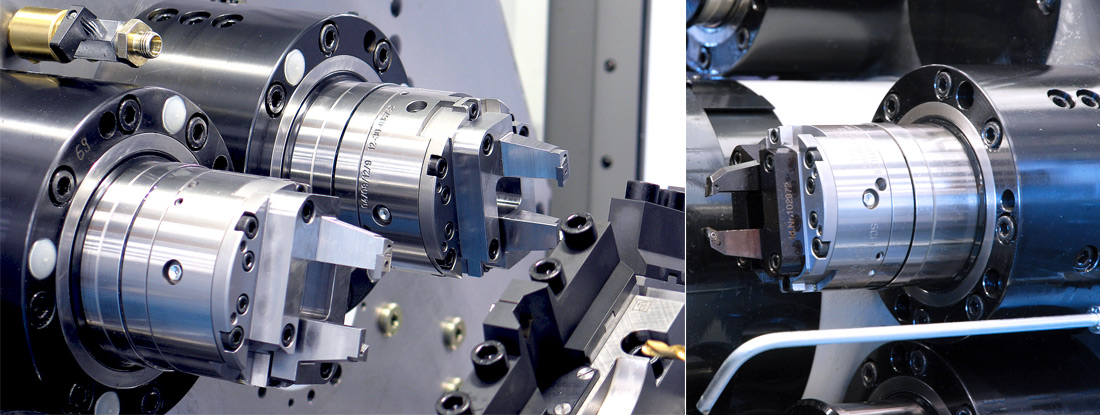

The Flexmaster Evolution offers the possibility to use the bigger HSK 40 machining units for radial milling operations (thread milling/contour milling) as well as the built in angle milling cutter for the end milling (width across flats, polygonal milling, slotting, boring, milling of contours…)

The front doors of machines with a maximum of two radial units can now be completely opened and will offer even more comfortable access to the machining units.

An essential goal while developing the Flexmaster Evolution was achieving changeover times of a maximum of 2 hours for skilled workers. This goal can be easily now by machining from bar, including the change of the clamping chucks, the change of tools and the change of the CNC program.

Sample applications

Specifications

Max. workpiece diameter:

bar 42 mm

single part 50×50 mm- Max. workpiece length: 180 mm

- Clamping stations: 8

- Output parts per minute: 10-15 pieces

- Machining units: max. 17 (14 axial, 3 radial)

- Max stroke machining units (standard): 90 mm

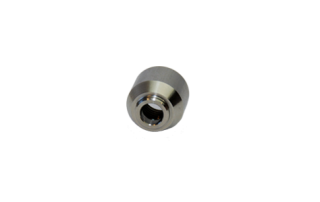

- Clamping: hydraulic jaws/ collets

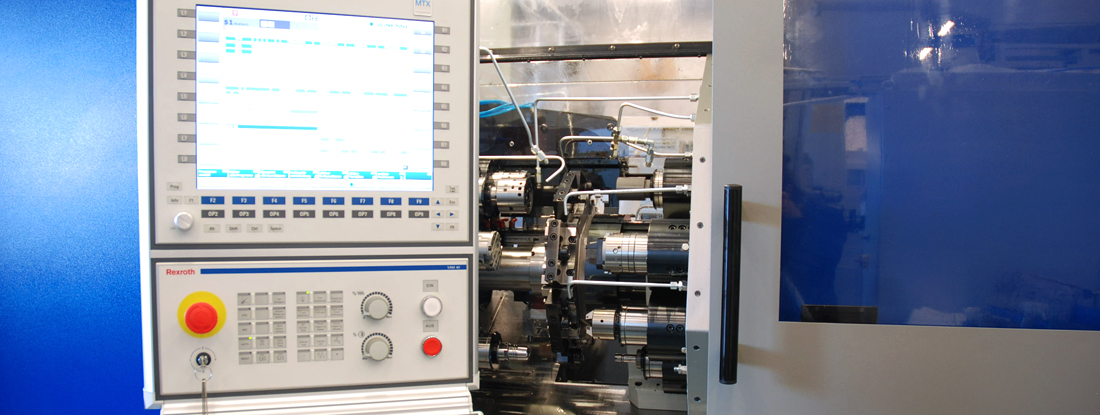

- Control: CNC Bosch MTX

- Quill feed: CNC

- Weight (depending on equipment): 8.500 kg

- Dimensions (machine only): 2,8m x 1,4m x 2,5m