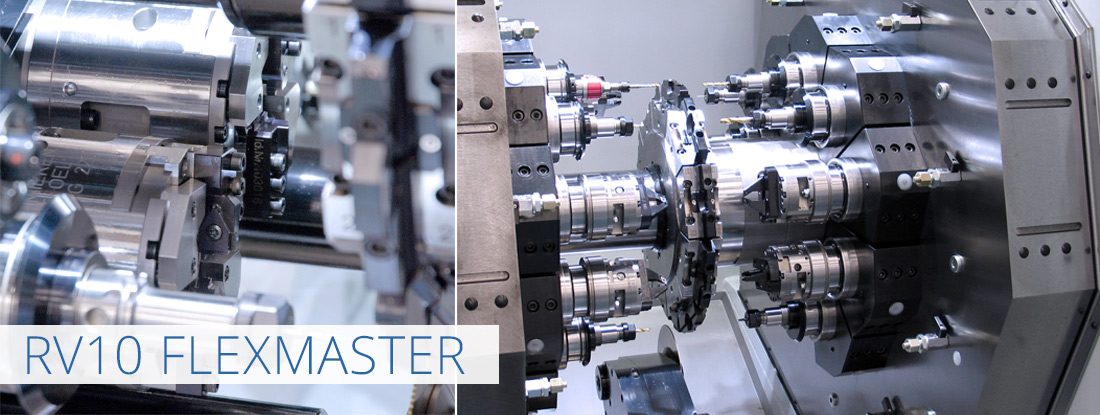

RV10 FLEXMASTER

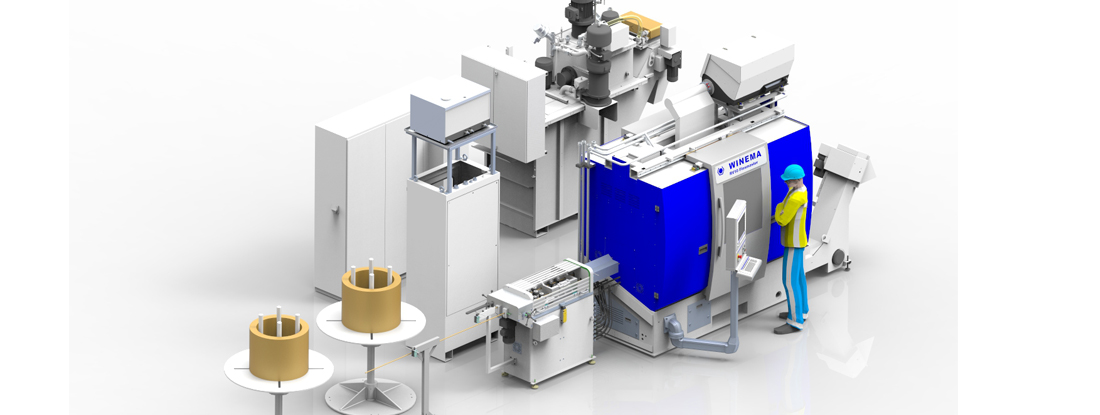

The RV 10 Flexmaster is the further developed Flexmaster concept for smaller parts. This rotary indexing machine is designed for a maximum output with high cycle times and short set-up times. The first glance into the machining area shows a clean and very structured working area with all working units easily accessible for the workers. The RV 10 Flexmaster is the answer to increasing numbers of set-ups needed due to faster changing variations of parts, to shorter life cycles of parts and to new and more difficult materials. With these new rotary indexing machines, you will be able to meet the demands of the changing markets and still achieve the high outputs of mechanical transfer machines.

RV 10 Flexmaster achieves sensationally short cycle times due to the dynamic direct drive of the indexing table; the indexing time of the table is under 0.3 seconds.

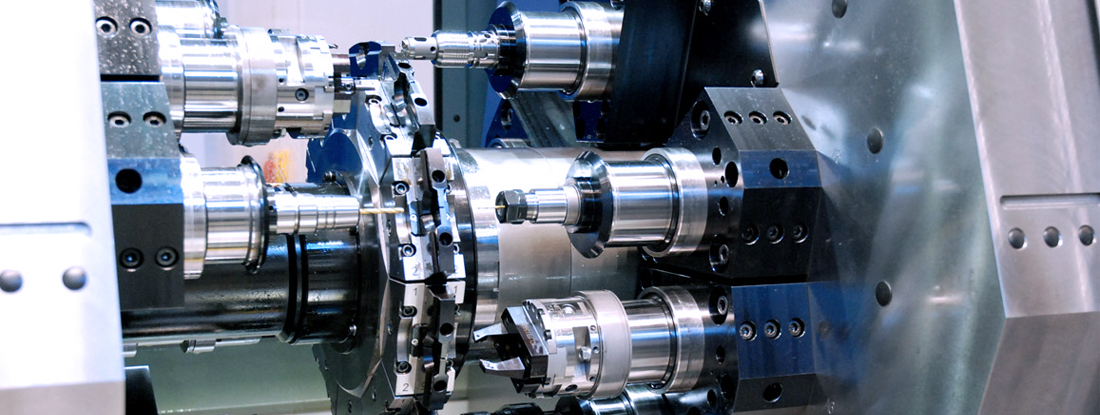

The standing indexing table has 10 clamping stations with centric clamping jaws. The workpiece can be processed with a maximum of 18 axial and 4 radial machining units.

In addition to these units, the RV 10 Flexmaster offers the possibility to add a plunge cut unit which allows to plunge cut the bar before it is clamped and provides the opportunity to clamp the workpiece on the diameter already finished with the plunge cut unit.

With this unit, the plunge cut can be machined not only by feeding from the ring but also with feeding by bar without producing remaining pieces that are very long. During the machining, the workpiece is clamped in a standard collet chuck.

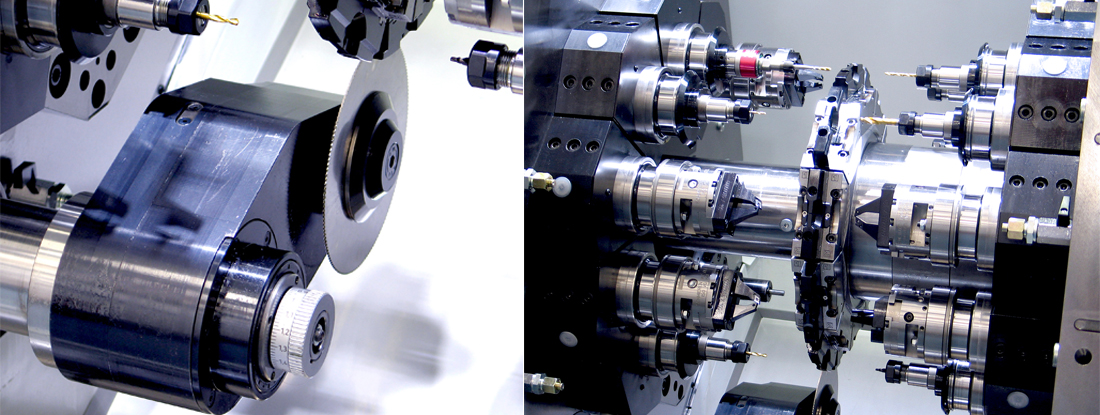

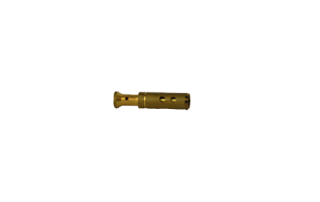

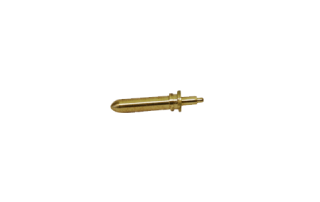

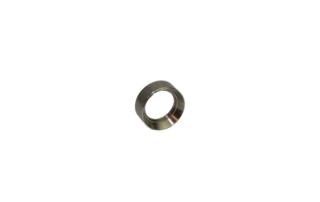

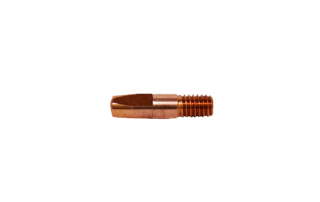

Sample applications

Specifications

Max. workpiece diameter:

bar 13 mm

single part 16 mm- Max. workpiece length: 80 mm

- Clamping stations: 10

Output parts per minute: 4-50 pieces

Double feeding: 10-80 pieces- Machining units: max. 22 (18 axial, 4 radial)

- Max stroke machining units (standard): 90 mm

- Clamping: hydraulic jaws/ collets

- Control: CNC Bosch MTX

- Quill feed: CNC

- Weight (depending on equipment): 6.500 kg

- Dimensions (machine only): 2,4m x 1,2m x 2,1m