RV30

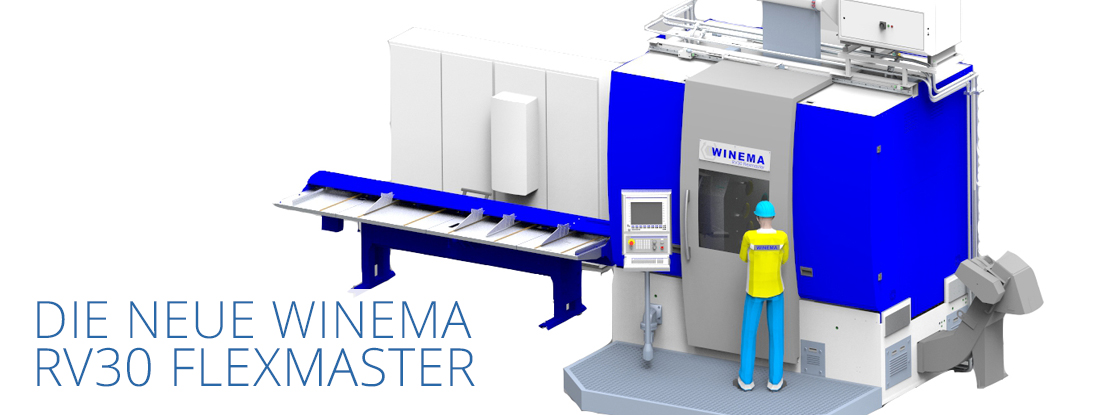

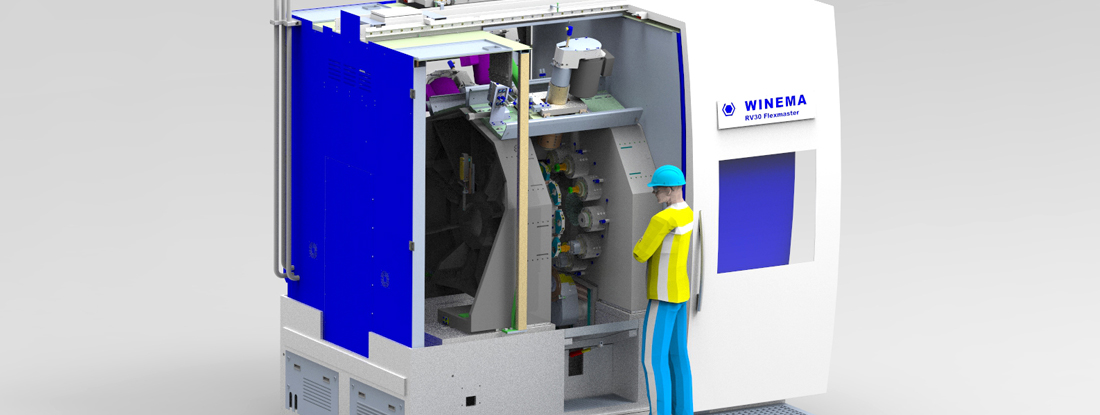

WINEMA’s RV30 Flexmaster expands the Flexmaster concept for the production of medium and large workpieces with diameters between 20 – 50 mm. Just like the entire RV series, the new RV30 is also constructed for maximum output with exemplary equipping capabilities. The 10 clamping stations combined with the optional 3 axle units situated horizontally and axially offer the best prerequisites for the machining of more complex components. A growing number of models, shorter product life cycles, modifications of the component, new materials: With the Winema RV30 Flexmaster you can adjust to the changing requirements of the market and still produce quantities which used to be exclusively achieved by cam-controlled machines.

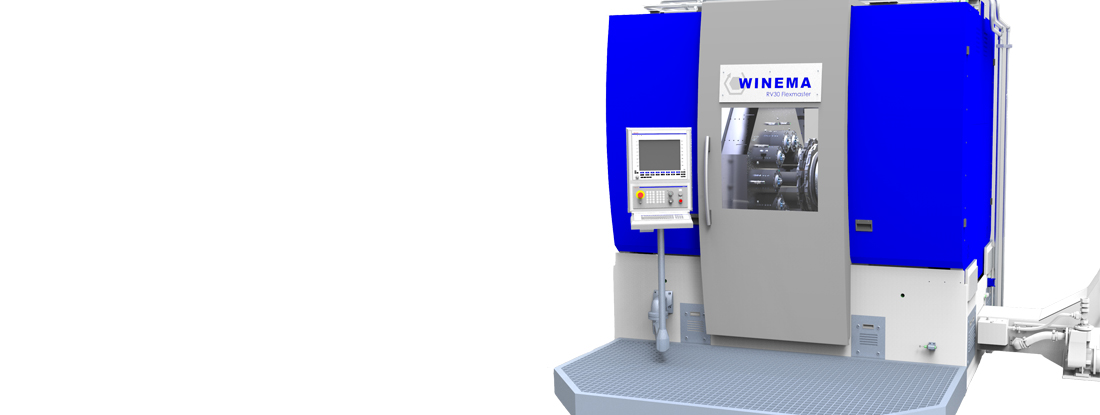

– the design of the welding and cast construction with the support of current FEM calculations and simulation ensure the best possible geometric precision.

– The functional and attractive machine design allows the best accessibility for individual machine equipment and maintenance tasks.

– Best possible seal on the machine doors by pneumatically applied seals.

– Shavings in the work area are funnelled into the shavings conveyor installed in the centre of the machine.

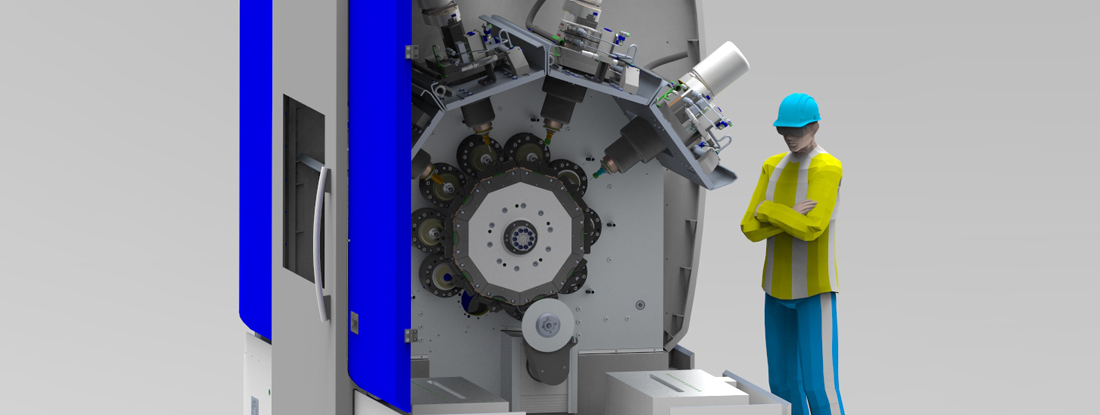

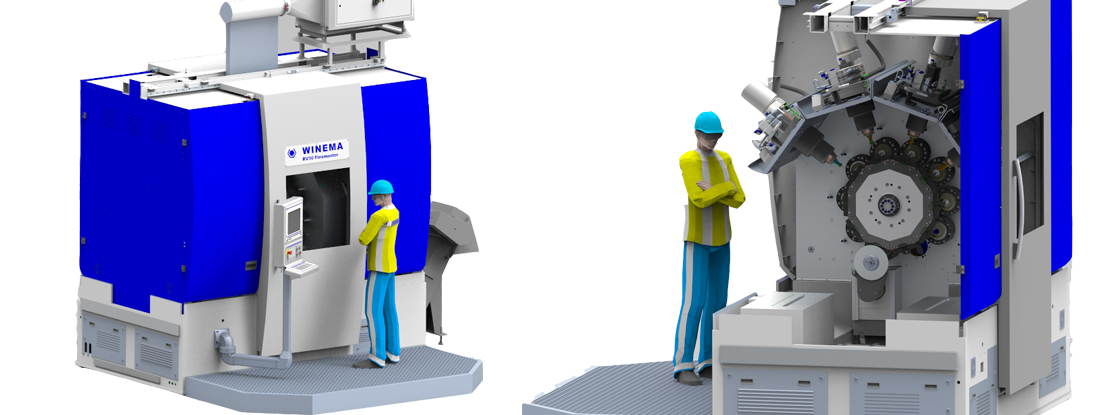

The double switching allows an optimized assignment of the 10 clamping stations. This model allows 2 radial machining processes for each workpiece. Also, 2 front spindle units can be placed in front of the indexing table. This model also allows double productions of more complex workpieces.

Max. workpiece diameter:

bar 15mm

single part 50mm- Max. workpiece length: 200 mm

- Clamping stations: 10

- Output parts per minute: 4-50

- Machining units: max. 22 (18 axial, 4 radial)

- Max stroke machining units (standard): 90 mm

- Clamping: hydraulic jaws/collets

- Control: CNC Bosch MTX

- Quill feed: CNC

- Weight (depending on equipment): 17000 kg

- Dimensions (machine only): 3,07m x 1,85m x 3,04m